Active components of an active plate

The continuous application of force by an active plate can be achieved by three mechanisms: (1) orthodontic screws, (2) spring components, or (3) elastics.

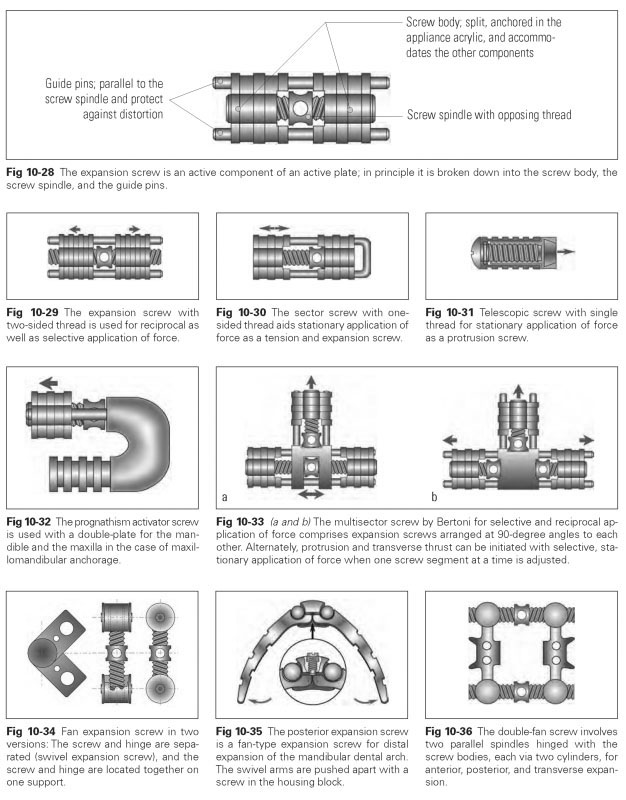

Orthodontic screws actively exert an effect on the teeth and dental arches via the baseplate margin. The screws currently available basically have the same structure and comprise the screw body, the screw spindle, and the guide pins (Fig 10-28). The screws are made from steel alloys resistant to conditions in the mouth; the screw body can be made of plastic or nonferrous metal alloys.

The screw body is divided, anchored in the acrylic of the appliance, and transfers the screw forces to the parts of the appliance. The screw spindle and the guide pins are fitted in parallel in the screw body. The screw body, spindle, and guide pins may be placed in a closed housing where the thread and guide tracks are captured in metal. However, screws are also available as skeletal finished parts where the thread and guide tracks lie in the acrylic of the appliance.

The screw spindle can have an opposing thread or a simple, one-sided thread. The screw with an opposing thread is used in reciprocal application of force, so that the split baseplate appliance transfers even, equal forces on both sides from the middle of the screw to the dental arches. The screw with a one-sided thread is used in stationary anchorage so that the large segment of the appliance transfers the force on one side to the segment being moved.

The pitch of the spindles is not equal in all screw designs but is between 0.64 and 0.90 mm for a rotation of 360 degrees. The overall expansion width, depending on the design and dimensions of a screw, is between 3 and 8 mm. If the spindle has an opposing thread, 360-degree rotation of the spindle achieves twice the pitch (expansion).

The guide pins are arranged parallel to the screw spindle in the screw body. As a result, the segments of the appliance are protected against twisting forces, and smooth running of the screw is guaranteed. In addition, it prevents the thread from winding back under stress.

The mechanical effect of the screws is based on clamping the appliance plate between the two segments of the dental arch being corrected. The clamping is made possible by the periodontal mobility of the teeth. The expansion of a plate by twisting the screw thread is matched to the width of the periodontal space to prevent any damage. On average, a child's periodontal space is 0.3 mm wide. A quarter turn of a screw with an overall thread pitch of 8.0 mm will narrow the periodontal space by 0.1 mm during reciprocal application of force.

The pressure effect achieved by the screw has to be so large that remodeling processes are initiated and remain continuously stimulated with a quarter turn per week. At the same time, the compressive forces must not stop blood circulation. Studies have proved the practicability of screws by comparing the degree of tooth loosening as a result of screws versus springs, showing that the screws caused markedly less tooth loosening.

Screws are classified according to their form and function. A distinction is made on the basis of the thread design and movement options:

- The expansion screw with two-sided thread is used for reciprocal application of force but also for selective application of force achieved by skillfully controlling the split between screw segments (Fig 10-29)

- The sector screw is used for moving individual sectors of the appliance during stationary application of force as a single-thread screw (Fig 10-30). As a tension (or lag) screw, it is screwed apart when incorporated, and the gap between the sectors is widened in keeping with the width of pull. If the screw is twisted together, the tensile effect enforces correction of the dental arch or single-tooth movement.

- The telescopic screw with a thread direction is used for single-tooth movement and made from acrylic or metal (Fig 10-31).

- The swivel expansion screw has two threads but no guide pins; instead it has a separate hinge that is fitted dorsally to the plate edge at the appliance gap. When the expansion screw is opened, the dental arch can be expanded in the anterior region, which is why the appliance plate should extend very far dorsally. The hinge may also be replaced by a wire.

Figures 10-32 to 10-36 show other varieties of orthodontic screws.