Activator fabrication

First, two models are prepared on which the activator is to be fabricated from acrylic, and two duplicates are produced on which the activator is ground. A construction bite record is then fabricated to show the two models in relation to each other in the occlusal position that the activator is intended to enforce. The jaws lie in the construction bite just as they are meant to be positioned after the treatment. Isometric muscle contractions are produced by the construction bite when it goes 6 to 10 mm beyond the rest position in the vertical plane.

The following criteria apply to the construction bite:

- The vertical distance between the maxillary and mandibular dentition is so large that no antagonist contact occurs; the most favorable distance is 6 mm. However, if only a slight sagittal shift of occlusal position is required, a 10-mm opening will be more effective. This is because the force exerted when biting out of the blocked position should actually produce the physiologic stimuli.

- The sagittal occlusal position is intended to indicate the regular position, in which the first molars are the fixed points when the other teeth are missing or displaced in a mixed dentition. In disto-occlusion, protrusion by one premolar's width corresponds to TMJ tolerance. The protrusive position can generally be achieved without difficulty if the sagittal distance of the anterior teeth is sufficient. Where there is a deep vertical overlap, the anterior teeth are first brought into the edge-to-edge position.

- In mesio-occlusion, the mandible must be pushed into the rearmost position, which is possible by about 2 mm dorsally. For pronounced prognathism, it usually becomes necessary to keep the movement of the activator doubleplates variable; ie, it must be possible to move them against each other with a screw in response to the progress of the adjustment.

- Lateral adjustment is performed by sliding the jaw midlines over each other. Where there are dental arch asymmetries, reverse articulation situations may arise, which also have to be readjusted by grinding on the activator. If necessary, unilateral dental arch constriction may be remedied by a swiveling activator wing.

In the construction bite, the working models are placed in the constructed relationship, and a wax squash bite is prepared.The construction bite taken on the model is tried in the patient's mouth, and then the models are placed in a fixator or a simple occluder with an occlusal height locking screw, with the hinge axis lying laterally next to the models.The oral cavity should be visible without any obstructions and accessible to working equipment. The models with the dorsal edges of the model base can also be lowered upright into plaster slurry, where they leave distinct impressions. Separator should be applied to the models so that they can be removed after the plaster has set. The plaster fixator is smoothed and shortened so that the models still have sufficiently secure guidance.

The labial bow is bent first. It contacts the maxillary incisors in the incisal third, incorporates the canine loop, is fed between the canine and the first premolar, and runs over the teeth in a palatal direction, where it is later anchored in acrylic.The canine loop can also be used for readjustment, depending on the progress of the treatment. The activator is then molded in wax: The double-plate fits closely to the palate and the alveolar process in the maxilla and mandible without restricting the floor of the mouth.

The palatal plate is reduced as far as possible. Therefore, the activator precisely covers the lingual surfaces of all the teeth as well as the occlusal surfaces of the posterior teeth and the mandibular anterior teeth. Basically, a wax splint covering the entire dentition is carved that reproduces the construction bite position.

A wax try-in can be carried out to check the position of the construction bite. However, the activator is generally fabricated immediately in acrylic. If the wax pattern can be accurately fabricated, which depends on the undercut situation and the shape of the teeth, the wax activator can be directly invested and completed in acrylic. Otherwise, the activator is invested on a model, usually that of the maxilla. Direct fabrication with self-curing acrylic, however, is the usual method. Once the activator is available in acrylic, it must be ground on the duplicate model.

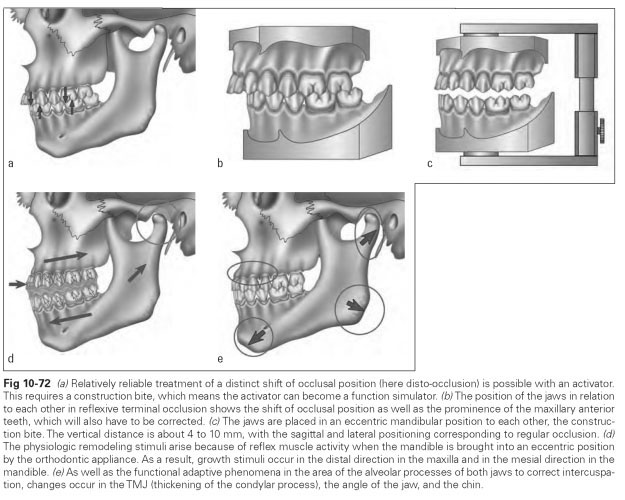

Figure 10-72 illustrates the shift in occlusal position possible with an articulator, demonstrating the concept of the construction bite.